CNC Engineering

Need more information?

Our Process

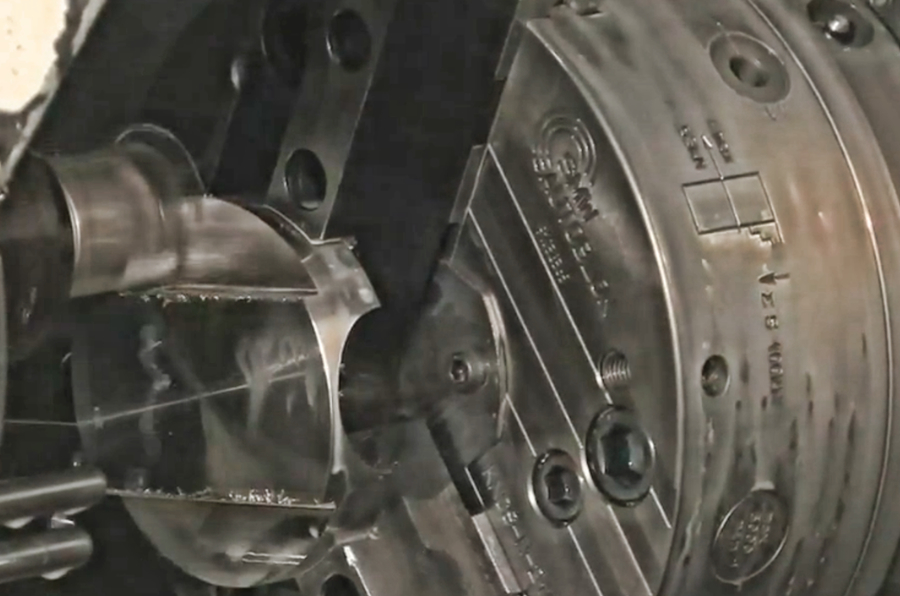

The engineering team works closely with the machining personnel, as well as tooling suppliers, to assure use of optimum tooling for the machining process. If a standard, off-the-shelf tool does not exist, the engineering team can design one. The goal is to create a robust, capable machining process, as well as to reduce cycle time, thereby providing best value for our customers.

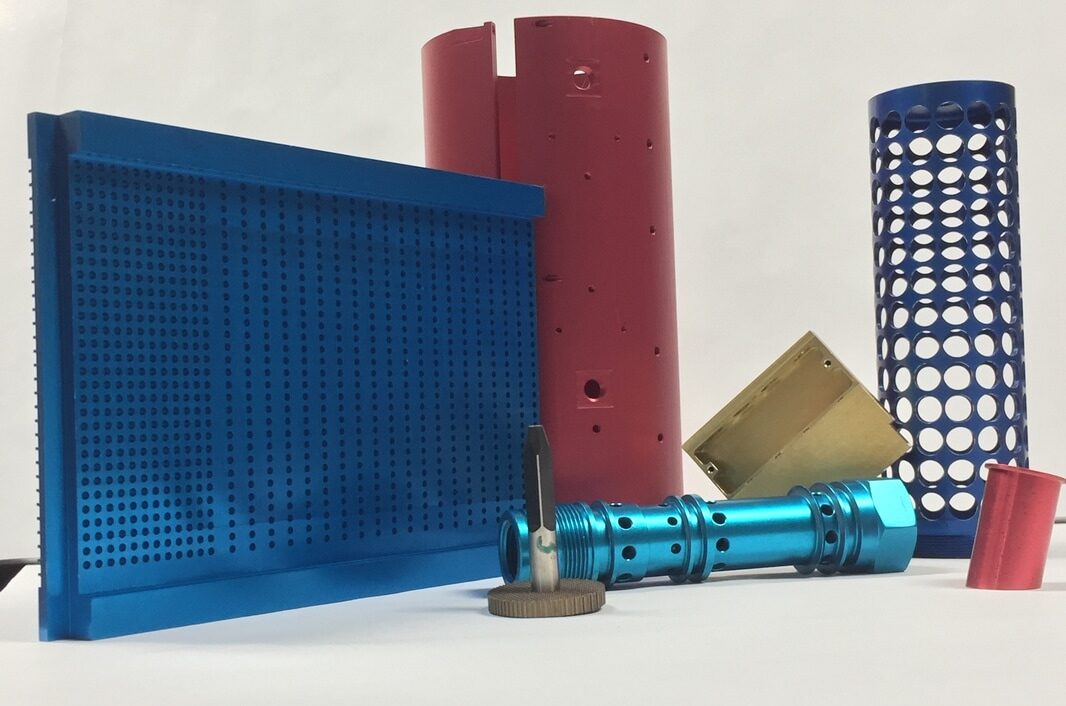

We can provide many secondary processes to take your project from start to finish. Our list of approved suppliers can add finishing touches such as Anodizing, Plating, Grinding, Heat Treating and many more.

Schultes Precision Engineering Support determines part flow requirements through the entire manufacturing process:

- Create bills of material for each part.

- Determine optimal equipment to be used for part processing.

- Develop specific manufacturing instructions for each part (Routing).

- Determine the effect sublet operations (e.g. plating, anodizing, heat treat, etc.) will have on part geometry post machining, and plan accordingly. This can involve simply marking up the customer part drawing, or creating a new manufacturing drawing, that will ultimately yield a part that meets all customer specifications after all operations are complete.

- Design special tools/gages/fixturing.

- Interact with customer engineering to improve manufacturability of parts, and clarify drawings, thereby reducing cost to the customer.

- Work together with QA department and MRB